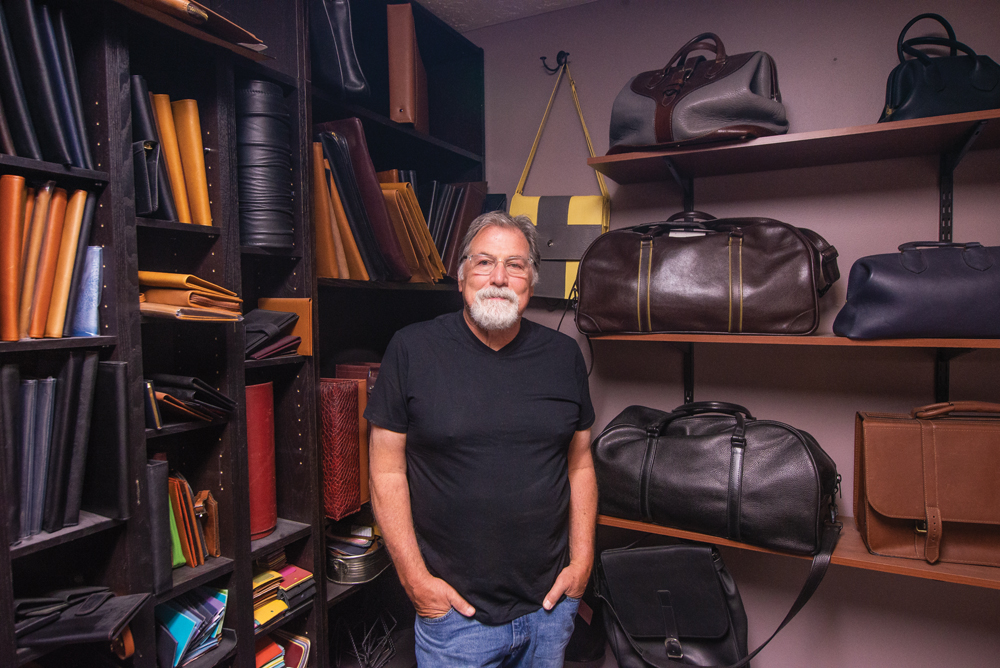

Mike Long, owner of Long Leather Works. Photos by Rodney Margison

BY PAUL BICKLEY

Forty years ago, Mike Long walked into a Florida leather shop and asked for a job. The owner asked if he knew how to make sandals. When he said no, the owner replied, “Yes, you do,” and, soon enough, he did. “I found it very easy,” Long says.

After a while, he was making other leather goods—wallets, purses, bags. Later he started doing repairs. “Repair work taught me how to make things,” says the owner of Long Leather Works. “I learned where things broke and how to make them better.”

A Rushville, Indiana, native who came to Bloomington in 1970 to attend Indiana University, Long, 66, launched his shop in 1983 in a one-car garage. Ten years later, he built and moved into his current south-side shop, a hard-to-find structure with no signage or retail space. He’s never needed it—contracts have driven business, to the tune of multiple $700,000 to $800,000 years. One year hit $1 million.

Long cuts the leather for military belts.

“When one thing died out, something else began,” Long says. One of those things was a 15-year stint designing and producing doctors’ bags and sample cases for Eli Lilly and Company. Another was producing notepad holders and pocket secretaries for Procter & Gamble. Locally, the company has done work for Cook Group, IU, and Ivy Tech Community College–Bloomington.

Long and his son Dave recently completed a contract to produce 50,000 belts for the U.S. Army and Marines. The New York–based contractor sought sheltered workshops, with work done by people with intellectual or developmental disabilities. It found one with Stone Belt Arc’s manufacturing program at The Arc of Lawrence County.

Long had worked with Stone Belt Arc, where he’d donated his belt-making apparatus. Stone Belt asked Long to size and cut the leather; it would finish the belts. For 50 weeks, the team manufactured 5,000 belts. “Arc kicked butt,” Long says. “That was one of the most rewarding things I’ve ever done.” The government recently requested 14,000 more belts.

“In 40 years, I’ve never grown tired of the smell of leather or of the sound good leather makes when I squeeze it,” Long says. “It’s the squeak of a person getting off a saddle or pulling on a good pair of boots.”

For more information, visit longleatherworks.com.